Chemical composition of 304 stainless steel C ≤ 0.08 Si ≤ 1.00 Mn ≤ 2.00 P ≤ 0.05 S ≤ 0.03 Cr 18.00-20.00 Ni (nickel) 8.00~10.50 -;

The chemical composition of 304L stainless steel is% C: ≤ 0.03, Si: ≤ 1.0, Mn: ≤ 2.0, Cr: 17.0 ~ 19.0, Ni: 8.0 ~ 11.0, S: ≤ 0.03, P: ≤ 0.035.

It can be seen that the main components of 304 stainless steel and 304L stainless steel are 18% chromium (Cr) and 8% nickel (Ni); The main difference between them is that 304L stainless steel is a low-carbon 304 steel. In general, the corrosion resistance of 304L stainless steel is similar to 304 stainless steel, but after welding or stress relief, the grain boundary corrosion resistance of 304L stainless steel is excellent

In terms of price, 304L stainless steel is higher than 304 stainless steel, and 304L stainless steel is low-carbon stainless steel, mainly applicable to welding process. When welding, 304L stainless steel can effectively reduce welding corrosion.

According to the hardness standard, 304 stainless steel is better than 304L stainless steel, because the carbon content directly affects the hardness of stainless steel. In addition, there are 304H stainless steel series. H indicates high carbon content.

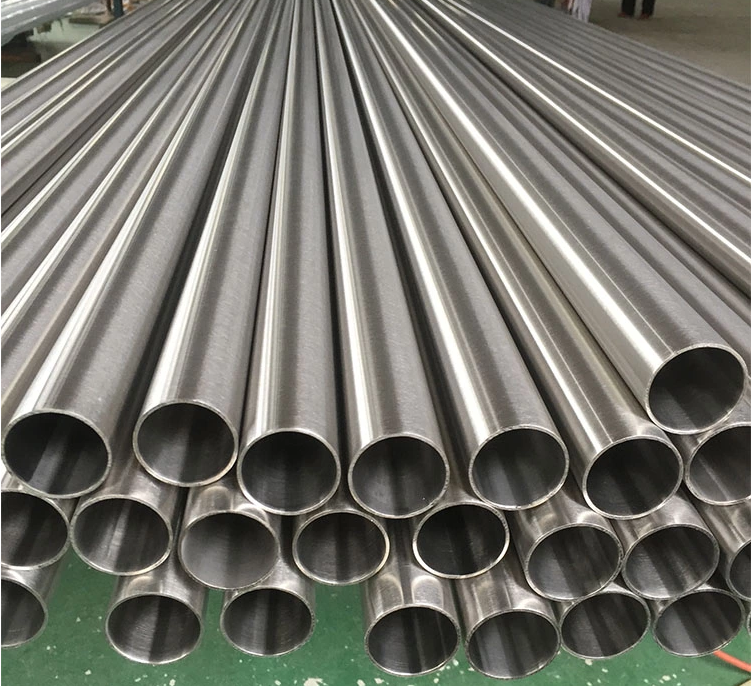

In terms of application, 304: 0Cr18Ni9, as a steel with a wide range of applications, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other hot workability are good, and there is no heat treatment hardening phenomenon (non-magnetic, use temperature of – 196 ℃~800 ℃). Household articles (Class 1 and 2 tableware, cabinets, indoor pipelines, water heaters, boilers, bathtubs), auto parts (windshield wipers, mufflers, molded products), medical appliances, building materials, chemicals, food industry, agriculture, and ship parts.

304L: 00Cr19Ni10 is a low C 304 steel. In general, its corrosion resistance is similar to that of 304 steel, but after welding or stress relief, its grain boundary corrosion resistance is excellent; It can also maintain good corrosion resistance without heat treatment, and the service temperature is – 196 ℃~ 800 ℃.

It is applied to outdoor machines in chemical, coal and petroleum industries with high requirements for grain boundary corrosion resistance, heat-resistant parts of building materials and zero parts with difficulties in heat treatment