CCS Ship Building Steel Plate.Shipbuilding steel sheet refers to the thin steel sheet and thick steel plate produced with special structural steel for shipbuilding and used to manufacture the hull structure of ships sailing in ocean, coastal and inland waterways. Structural steel for shipbuilding includes carbon steel and low-alloy steel, and the end of the steel number is marked with C (boat). Carbon steel has 2C, 3C, 4C and 5C, low alloy steel has 12MnC, 16MnC, 15MnTiC, 14MnVTiReC and other steel grades. The thickness is 2.5~50mm. Ship plate steel grades include A, B, D, E grades of general strength and AH32, DH32, EH32, AH36, DH36, EH36 grades of high strength; A and B ship plates of general strength can meet the requirements of Due to the requirements of technology and mechanical properties, the production process is relatively simple; while the production of D, E and high-strength ship plates needs to be realized by means of controlled rolling and controlled cooling process or heat treatment process with relatively complete equipment and equipment. At the same time, the internal steel purity requirements of the supplied billets are relatively high, especially the content of S, P, N, 0, H, etc. in the steel must be strictly controlled.

| Product Name | CCS Ship Building Steel Plate |

| Standard | CCS |

| Material | CCS Grade FQ70/EQ70/DQ70/AQ70/EQ63/FQ63/AQ63/EQ56/FQ56/AQ56/EQ51/FQ51/AQ51/EQ47/FQ47/AQ47/EH40/FH40/AH40/EH36/E/D/B/A |

| Technology | Hot Rolled ,Cold Rolled,Cold Drawn,Hot Expended |

| Tolerance | Control with in the standard, OD:+/-1%, WT:+/-5% |

| Application | Widely used in marine components, building steel structure components, substation auxiliary facilities, light industry, etc.

|

| Payment Terms | 1.FOB 30%T/T,70% Before shipment 2.CIF 30% Pre-payment , Balance must be paid before shipment 3.Irrevocable 100% L/C at sight |

| Third Party Inspection | SGS ,BV, MTC |

| Advantages | 1.Short delivery time2.Quality assurance

3.Competitive price, 4.Free Sample |

| Delivery Time | Within 25 days after receipt of advance payment |

| CCS Grade FQ70 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.18 | 0.55 | 1.6 | 0.02 | 0.02 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 690 | 770-940 | 14 | |||

| CCS Grade EQ70 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.2 | 0.55 | 1.7 | 0.025 | 0.025 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 690 | 770-940 | 14 | |||

| CCS Grade DQ70 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.21 | 0.55 | 1.7 | 0.035 | 0.035 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 690 | 770-940 | 14–16 | |||

| CCS Grade AQ70 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.21 | 0.55 | 1.7 | 0.03 | 0.03 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 690 | 770-940 | 14 | |||

| CCS Grade EQ63 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.2 | 0.55 | 1.7 | 0.025 | 0.025 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 620 | 720-890 | 15 | |||

| CCS Grade FQ63 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.18 | 0.55 | 1.6 | 0.02 | 0.02 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 620 | 720-890 | 15 | |||

| CCS Grade AQ63 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.21 | 0.55 | 1.7 | 0.03 | 0.03 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 620 | 720-890 | 15 | |||

| CCS Grade EQ56 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.2 | 0.55 | 1.7 | 0.025 | 0.025 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 550 | 670-830 | 16 | |||

| CCS Grade FQ56 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.18 | 0.55 | 1.6 | 0.02 | 0.02 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 550 | 670-830 | 16 | |||

| CCS Grade AQ56 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.21 | 0.55 | 1.6 | 0.03 | 0.03 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 550 | 670-830 | 16 | |||

| CCS Grade EQ51 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.2 | 0.55 | 1.7 | 0.025 | 0.025 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 500 | 610-770 | 16 | |||

| CCS Grade FQ51 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.18 | 0.55 | 1.6 | 0.02 | 0.02 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 500 | 610-770 | 16 | |||

| CCS Grade AQ51 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.21 | 0.55 | 1.7 | 0.03 | 0.03 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 500 | 610-770 | 16 | |||

| CCS Grade EQ47 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.2 | 0.55 | 1.7 | 0.025 | 0.025 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 460 | 570-720 | 17 | |||

| CCS Grade FQ47 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.18 | 0.55 | 1.6 | 0.02 | 0.02 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 460 | 570-720 | 17 | |||

| CCS Grade AQ47 Shipbuilding Steel Plate | |||||

| C max | Si max | Mn | P max | S max | N max. |

| 0.21 | 0.55 | 1.7 | 0.03 | 0.03 | 0.02 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||

| 460 | 570-720 | 17 | |||

| CCS Grade EH40 Shipbuilding Steel Plate | |||||||||||||

| C max | Si max | Mn | P max | S max | Als | Nb | V | Ti max. | Cu max. | Cr max. | Ni max. | Mo max. | N max. |

| 0.18 | 0.5 | 0.90-1.60 | 0.025 | 0.025 | 0.015 | 0.02-0.05 | 0.05-0.10 | 0.02 | 0.35 | 0.2 | 0.4 | 0.08 | - |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||||||||||

| 390 | 510-660 | 20 | |||||||||||

| CCS Grade FH40 Shipbuilding Steel Plate | |||||||||||||

| C max | Si max | Mn | P max | S max | Als | Nb | V | Ti max. | Cu max. | Cr max. | Ni max. | Mo max. | N max. |

| 0.16 | 0.5 | 0.90-1.60 | 0.02 | 0.02 | 0.015 | 0.02-0.05 | 0.05-0.10 | 0.02 | 0.35 | 0.2 | 0.8 | 0.08 | 0.009 |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||||||||||

| 390 | 510-660 | 20 | |||||||||||

| CCS Grade AH40 Shipbuilding Steel Plate | |||||||||||||

| C max | Si max | Mn | P max | S max | Als | Nb | V | Ti max. | Cu max. | Cr max. | Ni max. | Mo max. | N max. |

| 0.18 | 0.5 | 0.90-1.60 | 0.03 | 0.03 | 0.015 | 0.02-0.05 | 0.05-0.10 | 0.02 | 0.35 | 0.2 | 0.4 | 0.08 | - |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||||||||||

| 390 | 510-660 | 20 | |||||||||||

| CCS Grade EH36 Shipbuilding Steel Plate | |||||||||||||

| C max | Si max | Mn | P max | S max | Als | Nb | V | Ti max. | Cu max. | Cr max. | Ni max. | Mo max. | N max. |

| 0.18 | 0.5 | 0.90-1.60 | 0.025 | 0.025 | 0.015 | 0.02-0.05 | 0.05-0.10 | 0.02 | 0.35 | 0.2 | 0.4 | 0.08 | - |

| Yield Strength (MPa) min. | Tensile Strength (MPa) | Elongation min. % | |||||||||||

| 355 | 490-630 | 21 | |||||||||||

The steel plate is a flat steel that is cast with molten steel and pressed after cooling.

The steel sheet is flat, rectangular and can be directly rolled or cut from wide steel strips.

The steel plates is divided according to the thickness, the thin steel plate is less than 4 mm (the thinnest is 0.2 mm), the medium-thick steel plate is 4-60 mm, and the extra-thick steel plate is 60-115 mm.

Steel sheets are divided into hot rolling plate and cold rolling plate according to rolling.

1. Hot Rolled Steel Plate

Hot rolling processing methods include hot rolling, forging, extrusion and other methods.

2. Cold Rolled Steel Plate

Cold rolling processing methods include cold rolling, cold drawing and cold drawing, cold bending, cold extrusion and other methods.

The cold rolling method is to continue processing the hot rolled steel below the recrystallization temperature to make it cold rolled steel. Using cold rolling processing method can improve the mechanical properties of steel, and obtain products with high dimensional accuracy and certain smoothness.

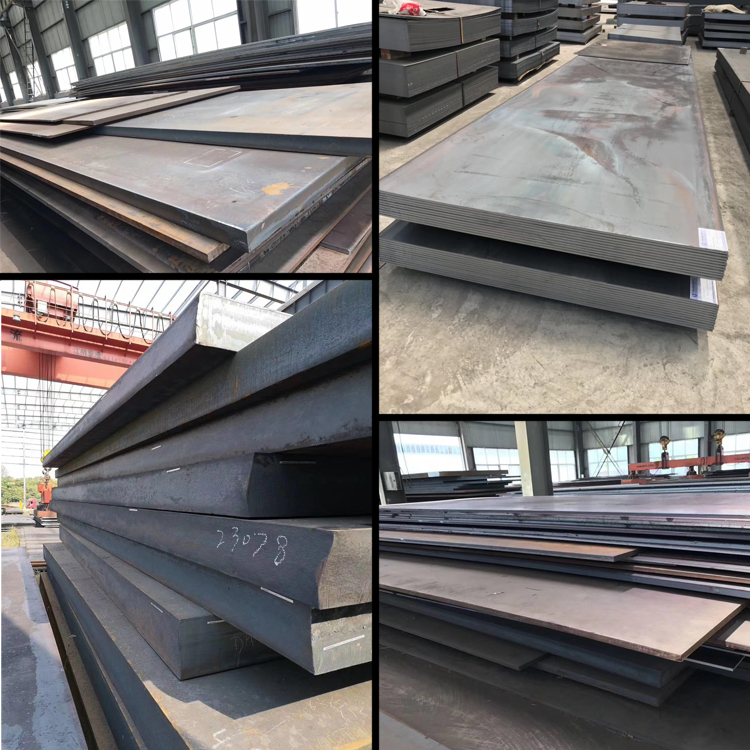

Q: Are you a manufacturer?

A: Yes , we are a Carbon Steel Sheet manufacturer, We have own factory, which is located in Shandong,China. We have a leading power in producing and exporting carbon steel plate,cold rolled steel sheet, etc. We promise that we are what you are looking for.

Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

Q: Do you have quality control?

A: Yes, we can accept BV, SGS third inspection .

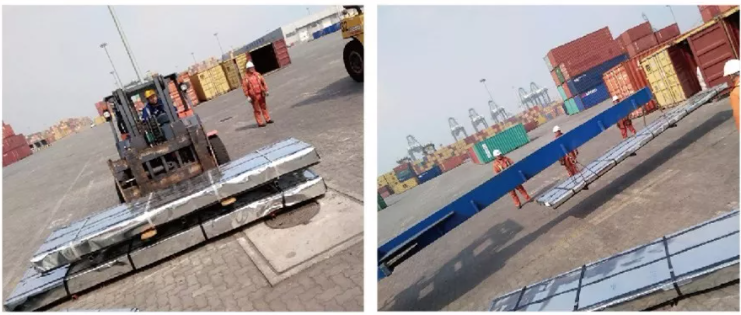

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q:How can we get the offer?

A:Please offer the specification of the product,such as material,size,shape,etc.So we can give the best offer.

Q:Can we get the some samples?Any charges?

A:Yes,you can get available samples in our stock.Free for real samples,but customers need to pay the freight cost.

Q: How do you make our business long-term and good relationship ?

A: 1.We keep good quality and competitive price to ensure our customers’ benefit.

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.