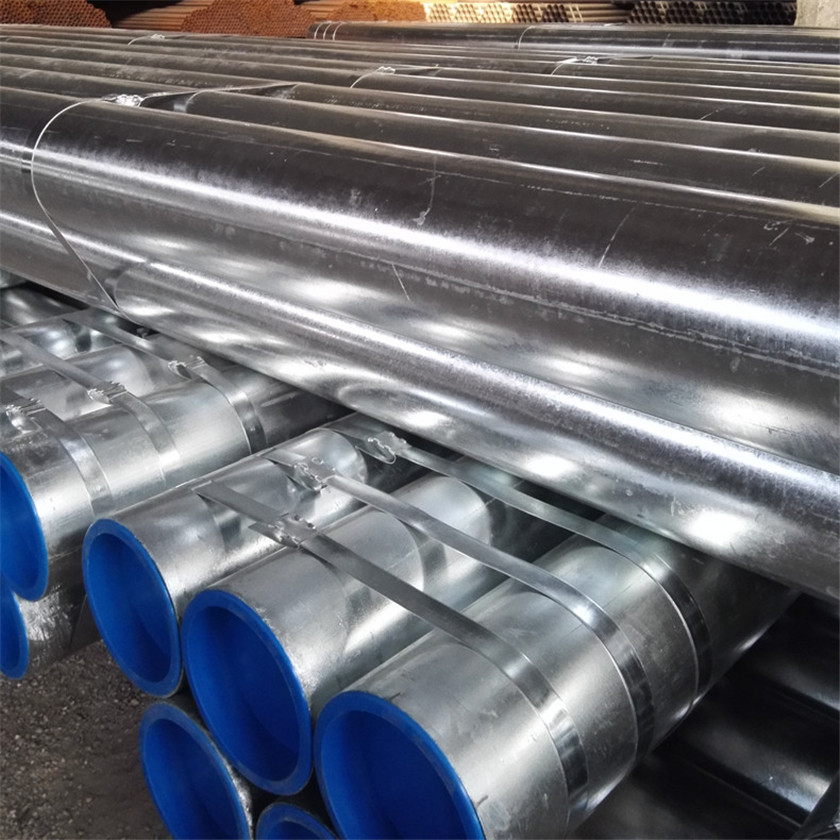

Product Introduction

Hot dip galvanized steel pipes are widely used in manufacturing industries such as construction, machinery, coal mine, chemical industry, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, greenhouse construction, etc.

Welded steel pipe with hot-dip or electro galvanized coating on the surface of galvanized steel pipe. Galvanizing can increase the corrosion resistance of steel pipes and prolong their service life. Galvanized pipes have a wide range of uses. In addition to being used as pipeline pipes for water, gas, oil and other general low pressure fluids, they are also used as oil well pipes and oil pipelines in the petroleum industry, especially in offshore oil fields, as well as pipes for oil heaters, condensate coolers, and coal distillate oil washing oil exchangers in chemical coking equipment, as well as pipes for trestle pipe piles and support frames in mine tunnels.

Hot dip galvanized pipe is to make molten metal react with iron substrate to produce alloy layer, so that the substrate and coating can be combined. Hot galvanizing refers to pickling the steel pipe first. In order to remove iron oxide on the steel pipe surface, after pickling, the steel pipe is cleaned in ammonium chloride or zinc chloride aqueous solution or mixed ammonium chloride and zinc chloride aqueous solution tank, and then sent to the hot dip tank. Hot dip galvanizing has the advantages of even coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the hot-dip galvanized steel pipe substrate and the molten plating solution, forming a corrosion resistant zinc iron alloy layer with compact structure. The alloy layer is integrated with pure zinc layer and steel pipe matrix, so its corrosion resistance is strong.

Product details

| Thickness | 0.5-8mm;or as required | ||||||||

| Dimensions | 10-3000mm;(1/2inch~40inch)Dimensions | ||||||||

| Length: | 2000-12000mm,or as required | ||||||||

| Technique | Hot Rolled | ||||||||

| Standard: | ASTM,JIS,GB,DIN,EN | ||||||||

| Payment Terms | T/T, L/C at sight,West Union | ||||||||

| Heat Treatment | Annealed; Quenched; Tempered | ||||||||

| Certification: | CE, ISO, SGS,BV,Mill Certificate | ||||||||

| price terms | FOB,CFR,CIF,EXW, CPT | ||||||||

| Grade | Q195—Grade B, SS330, SPC, S185Q215—Grade C,CS Type B, SS330, SPHC,Q235—Grade D, SS400, S235JR, S235JO, S235J2,Q345—SS500, ST52,S355JR | ||||||||

| Delivery Detail | Standard has Stock; Normal About 3-5days; Custom-made 15-20days;According to order’s quantity. | ||||||||

| Packing | standard export packing (inside:water proof paper,outside:fumigated wooden box)Hexagon Shape Bundle, Covered With Tarpaulin, Containers Or In Bulk | ||||||||

Product area display

| Steel grade | GB | JIS | ASTM | DIN | |||

| Brand | Brand | Brand | Steel number | Steel number | Material number | Standard | |

| Carbon | (Q235) | GGP | G3452 | (A53- F) | (St33) | 1.0033 | DIN1626 |

| Steel pipe | STPY41 | G3457 | A283-D | ||||

| 10 | STPG38 | G3454 | A135-A | (St37) | 1.011 | DIN1626 | |

| A53-A | |||||||

| STPG38 | G3456 | A106-A | St37-2 | 1.0112 | DIN17175 | ||

| STS38 | G3455 | St35.8 | 1.0305 | DIN1629/4 | |||

| St35.4 | 1.0309 | ||||||

| STB30 | G3461 | A179-C | St35.8 | 1.0305 | DIN17175 | ||

| A214-C | |||||||

| STB33 | G3461 | A192 | St35.8 | 1.0305 | DIN17175 | ||

| A226 | |||||||

| STB35 | G3461 | St35.8 | 1.0305 | DIN17175 | |||

| 20 | STPG42 | G3454 | A315-B | (St42) | 1.013 | DIN1626 | |

| A53-B | St42-2 | 1.0132 | |||||

| STPT42 | G3456 | A106-B | St45-8 | 1.0405 | DIN17175 | ||

| STB42 | G3461 | A106-B | St45-8 | 1.0405 | DIN17175 | ||

| STS42 | G3455 | A178-C | St45-4 | 1.0309 | DIN1629/4 | ||

| A210-A-1 | |||||||

| Low alloy | 16Mn | STS49 | G3455 | A210-C | St52.4 | 1.0832 | DIN1629/4 |

| Steel pipe | STPT49 | G3456 | St52 | 1.0831 | DIN1629/3 | ||