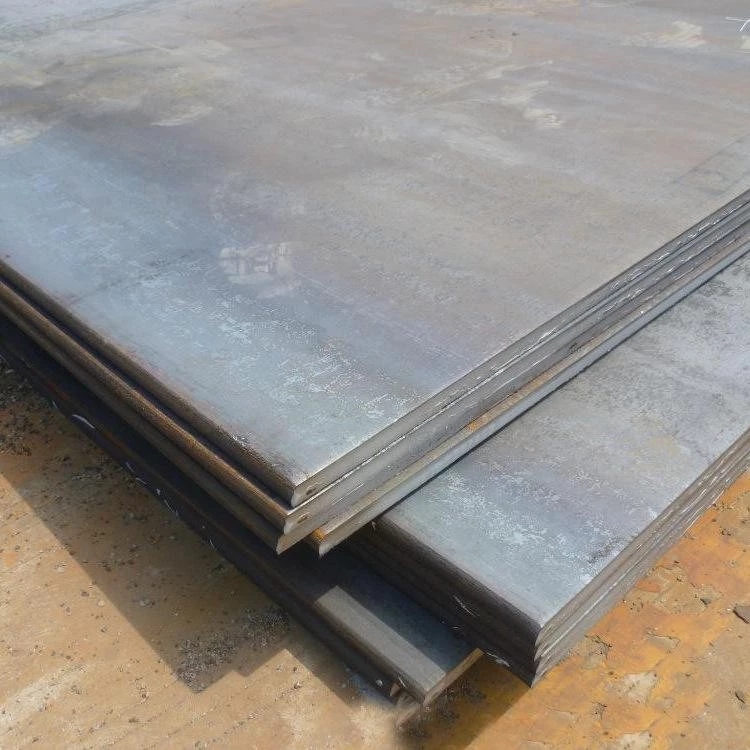

Pressure vessel plate is a steel plate used to manufacture steam boilers, pressure vessels and other pressure vessel structural parts. This kind of steel plate is subject to certain air pressure and water pressure, as well as different temperature environments, such as high, medium and low temperature, so the requirements for this kind of steel plate are relatively strict.

Type: According to the composition, it can be divided into two categories: carbon steel plate and alloy steel plate; according to the strength, it can be divided into high, medium and low voltage steel plates; according to the use environment, it can be divided into high, medium and low temperature steel plates and corrosion-resistant steel plates.

The thickness of pressure vessel plates generally ranges from 5 to 200mm, which is divided into several thickness specifications. National standards list recommended plate dimensions and allowable deviations. Appearance quality (1) The shape of the steel plate: such as sickle curve, flatness, right angle, etc. (2) Surface defects: Surface defects of steel plates mainly include cracks, scars, flattened bubbles, impurities, bulges, pores, pressed iron oxide scale, etc. Due to safety requirements, pressure vessel steel plates have strict requirements on surface and internal defects. The above defects are generally not allowed to exist. However, it is allowed to be removed with appropriate methods, and the removal site should be flat. Its thickness shall not exceed the allowable difference in steel plate thickness. Generally, mezzanines are not allowed. Chemical composition index:

①Carbon steel plate: mainly detects carbon, silicon, manganese, phosphorus and sulfur content. Some carbon steel also contains a certain amount of copper, chromium, nickel, molybdenum, vanadium and other elements. Among them, carbon is the main factor that determines the strength of steel plates, that is, the strength of steel plates increases as the carbon content increases. The carbon content of carbon steel plates is between 0.16 and 0.33%. Manganese and silicon also have the effect of improving materials and increasing strength. Silicon: 0.10~0.55%, manganese: 0.4~1.6%. Some standards have no silicon and manganese requirements for ordinary boiler plates, and copper is below 0.30%. Other standards such as Japan and Russia do not have copper content requirements. Some high-quality steels contain chromium (less than 0.25%), nickel (less than 0.30%), molybdenum (less than 0.10%), and vanadium (less than 0.03%).

② Low alloy steel plate: In addition to the elements contained in carbon steel, there are also a certain amount of molybdenum, chromium, nickel, vanadium, etc. There are many grades of low alloy steel, among which the more commonly used standards are as follows: 1/2 molybdenum, 1/2Mo-B steel: ASTM A204, JIS G3107; Mn-1/2Mo1/2Mo, Mn-1/2Mo-V, Mn -1/2Mo-1/4Ni, Mn1/2Mo-1/2N i steel: ASTM A302, A533, JIS G3119, G3120; 1Cr-1/2Mo, 11/4Cr-1/2Mo, 21/2Cr-1Mo, 3C r-1Mo, 5Cr-1/2Mo, 7Cr-1/2Mo, 9Cr-1Mo: JISG4109, ASTM A387, A533, DIN17155.

③Quenched and tempered high-strength steel plate: see ASTM A517, A537, A724, A734, JISG3115.

④ Low-temperature steel: including carbon steel and alloy steel. The chemical composition and mechanical properties can be found in ASTMA612, A 662, A735, A736, A738, A203, A645, and JIS G3126.

⑤Stainless steel: Please refer to JIS G4304, ASTM A240, AISI13, ΓOCT5632.

Post time: Sep-22-2023