Aluminum foil is a hot stamping material that is directly rolled into thin sheets by metallic aluminum. Its hot stamping effect is similar to that of pure silver foil hot stamping, so it is also called fake silver foil. Due to the soft texture, good ductility and silvery white luster of aluminum, if the calendered sheet is mounted on offset paper with sodium silicate and other substances to make aluminum foil, it can also be printed. However, the aluminum foil itself is easy to oxidize and darken in color, and will fade when rubbed or touched, so it is not suitable for hot stamping on the covers of books and periodicals that are stored for a long time.

Due to its excellent characteristics, aluminum foil is widely used in food, beverages, cigarettes, medicines, photographic substrates, household daily necessities, etc., and is usually used as its packaging materials; electrolytic capacitor materials; heat insulation materials for buildings, vehicles, ships, houses, etc.; can also Decorative gold and silver threads, wallpapers, various stationery prints and decorative trademarks of light industrial products, etc. Among the various uses mentioned above, the one that can make the most effective use of the performance of aluminum foil is as a packaging material. Aluminum foil is a soft metal film, which not only has the advantages of moisture-proof, air-tight, light-shielding, abrasion-resistant, fragrant, non-toxic and tasteless, but also because of its elegant silver-white luster, it is easy to process beautiful patterns and patterns of various colors. pattern, so it is more likely to be favored by people. Especially after aluminum foil is compounded with plastic and paper, the shielding property of aluminum foil is integrated with the strength of paper and the heat sealing property of plastic, which further improves the shielding performance against water vapor, air, ultraviolet rays and bacteria, etc. necessary for packaging materials. , greatly broadened the application market of aluminum foil. Since the packaged items are fully isolated from the light, moisture, and gas of the outside world, the packaged items are well protected. Especially for the packaging of cooked food, the use of this composite aluminum foil material can at least ensure that the food will not deteriorate for more than one year. Moreover, it is very convenient to heat and unpack, and is very popular among consumers.

thickness

Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to the difference in thickness.

① Thick foil (“heavy gaugefoil”): foil with a thickness of 0.1 to 0.2mm.

②Single zero foil (“medium gauge foil”): Foil with a thickness of 0.01mm and less than 0.1mm/.

③ Double zero foil (“light gauge foil”): The so-called double zero foil is a foil with two zeros after the decimal point when its thickness is measured in mm, usually an aluminum foil with a thickness less than 0.01, that is, an aluminum foil with a thickness of 0.005~0.009mm . In foreign countries, aluminum foil with a thickness of ≤40ltm is sometimes referred to as “light gauge foil”, and aluminum foil with a thickness of > 40btm is collectively referred to as “heavy gauge foil”.

shape

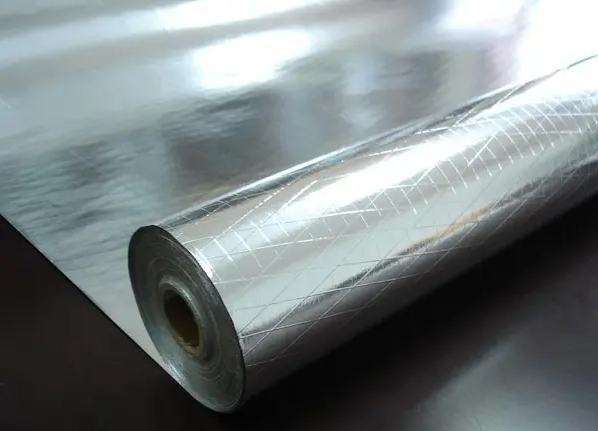

Aluminum foil can be divided into roll aluminum foil and sheet aluminum foil according to the shape. Most of the aluminum foil deep-processing wool is supplied in rolls, and sheet aluminum foil is only used in a few handicraft packaging occasions.

Aluminum foil can be divided into hard foil, semi-rigid foil and soft foil according to the state.

①Hard foil: Aluminum foil that has not been softened (annealed) after rolling, and if it has not been degreased, there will be residues on the surface. Therefore, the hard foil must be degreased before printing, laminating, and coating, and it can be used directly if it is used for forming.

②Semi-rigid foil: Aluminum foil whose hardness (or strength) is between hard foil and soft foil, usually used for forming processing.

③Soft foil: aluminum foil that has been fully annealed and softened after rolling. The material is soft and there is no residual oil on the surface. Flexible foils are used in most application areas such as packaging, lamination, electrotechnical materials, etc.

surface condition

Aluminum foil can be divided into one-side light aluminum foil and two-side light aluminum foil according to the surface state.

①Single-sided aluminum foil: double-rolled aluminum foil, one side is bright after being rolled, and one side is black. Such aluminum foil is called one-sided aluminum foil. The thickness of one side light aluminum foil usually does not exceed 0.025mm.

② Double-sided aluminum foil: single-rolled aluminum foil, both sides are in contact with the roll, and the two sides of the aluminum foil are divided into mirror two-sided aluminum foil and ordinary two-sided aluminum foil due to the different surface roughness of the roll. The thickness of two-sided light aluminum foil is generally not less than 0.01mm.

Post time: May-24-2023