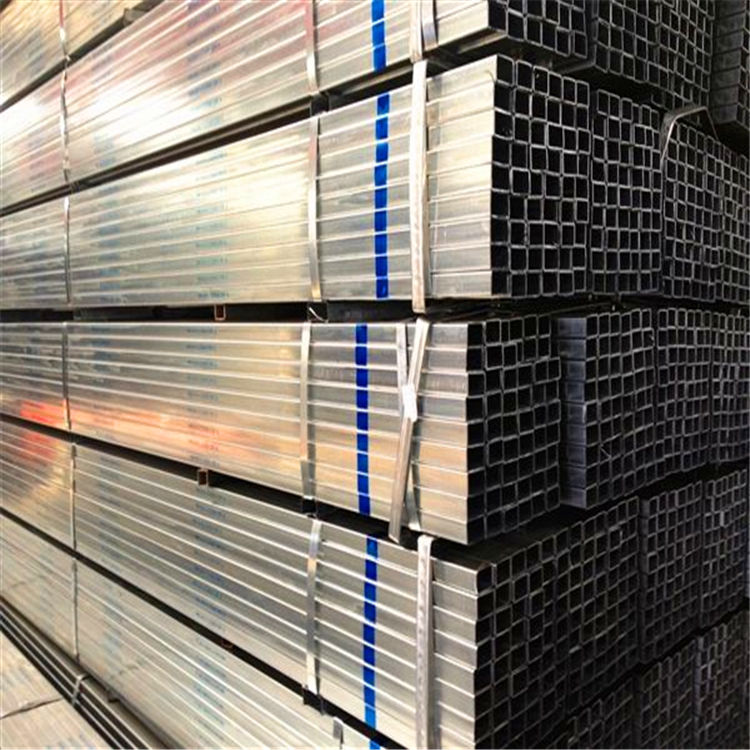

Square tube is a hollow square cross-section lightweight thin-walled steel tube, also known as steel cold-bent profile. It is a square section steel with a square cross-section shape and size made of Q235 hot-rolled or cold-rolled strip or coil as the base material, cold bending and then high-frequency welding. In addition to the thickening of the wall thickness, the corner size and edge straightness of hot-rolled extra thick-walled square tubes reach or even exceed the level of resistance welded cold-formed square tubes. Usually 50 pieces per pack. Square and rectangular tubes are also known as square and rectangular cold-formed hollow sections, referred to as square tubes and rectangular tubes, and their codes are F and J respectively.

What is the forming method of seamless square and rectangular tubes?

The hollow defect is that the upper tube is bent/the hollow bending side is synchronized with the timing. Due to the pressure of the upper roller and the lower roller, the forming force is simply beyond the zero boundary point, causing concave instability at the edge. In addition, it is also It reflects the stable control module and the operation process that creates quality. It is the opposite characteristic of rectangular tubes and the bending of the tubes caused by the gas. When the telescoping diameter is unstoppable the solid body can be bent, for example a rectangular top tube/spine bending synchronization and finishing gas bending strength is stopped. Gas bending can also be bent outside corners of < 0.2 tons and is not easy to solve the wall.

Basic principles of hot-dip galvanized square pipe processing technology

Galvanized pipes include hot-dip galvanized square pipes and electro-galvanized pipes. Hot-dip galvanized square pipes include wet method, dry method, iron ore method, redox reaction method, etc. The main difference between different hot-dip galvanizing methods is how to activate the surface of the pipe body after acid leaching cleaning of the seamless steel pipe to improve the hot-dip galvanizing quality. Dry and redox reaction methods are mainly used in current manufacturing, and their characteristics are shown in the table. The surface of the phosphated zinc layer is very smooth, high-density, and well-proportioned; it has excellent physical properties and corrosion resistance; zinc consumption is 60% to 75% lower than hot-dip galvanizing. Phosphating treatment has certain technical diversity, but this method must be used for single-layer coatings, double-sided coatings with different thicknesses of inner and outer coatings, and hot-dip galvanizing of thick-walled pipes.

A brief description of galvanized square and rectangular pipes is as follows

1. The general delivery length of galvanized square and rectangular pipes is 4000mm-12000mm, with 6000mm and 12000mm accounting for the majority. Square and rectangular tubes are allowed to be delivered with short and non-cut length products of no less than 2000mm, and can also be delivered in the form of spigot tubes, but the buyer must remove the spigot tubes when using them. The net weight of short-length and non-fixed-length products shall not exceed 5% of the total delivery volume. For square and rectangular pipes whose weight calculation formula exceeds 20kg/m, the net weight shall not exceed 10% of the total delivery volume. 2. The bending degree of galvanized square and rectangular pipes shall not exceed 2mm per meter, and the total bending degree shall not exceed 0.2% of the total length. 3. The allowable error of the wall thickness of galvanized square and rectangular pipes shall not exceed 10% of the positive and negative electrodes of the nominal pressure wall thickness when the wall thickness does not exceed 10mm, and 8% of the positive and negative electrodes of the nominal pressure wall thickness when the wall thickness exceeds 10mm. Outside the wall thickness of corners and welding areas.

The difference between galvanized seamless pipe, galvanized pipe and galvanized steel pipe.

Galvanized square and rectangular pipes are different from ordinary square and rectangular pipes. The main difference is that the outer wall is galvanized. The advantage of galvanizing is that it has stronger protective effect and strong corrosion resistance. The entire structure is made of zinc, forming a dense quaternary crystal. This crystal forms a barrier on the steel plate, thus effectively preventing corrosion factors from penetrating. Corrosion resistance comes from the strong protective barrier layer of zinc. When zinc provides sacrificial protection on trimmed edges, scratches, and abraded parts of the coating, the zinc forms an insoluble oxide layer and exerts a barrier protection function.

Post time: Apr-02-2024