To create much more price for clients is our company philosophy; purchaser growing is our working chase for High Quality for China Aluminum Extrusion Profile for Building Aluminium Profile Hear Sink Industry, Hope we can make a more superb potential with you as a result of our attempts from the future.

To create much more price for clients is our company philosophy; purchaser growing is our working chase for Aluminium Extrusion, China Aluminum Extrusion, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade items in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Product Description

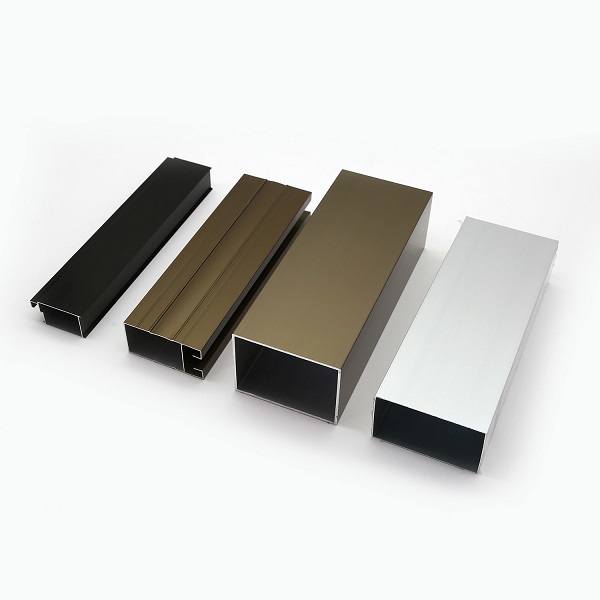

Anodized aluminum profile refers to a layer of dense aluminum oxide coated on the surface of aluminum and aluminum alloys. In order to prevent further oxidation, its chemical properties are the same as aluminum oxide. But unlike ordinary oxide films, anodized aluminum can be dyed with electrolytic coloring.

Anodizing can significantly improve the corrosion resistance of aluminum alloys, improve the surface hardness and wear resistance of aluminum alloys, and have good decorative properties after appropriate coloring treatment. Aluminum and its alloy anodized film coloring technology can be divided into 3 kinds: chemical dyeing, electrolytic coloring and electrolytic overall coloring. Chemical dyeing is to use the porosity and chemical activity of the oxide film layer to adsorb various pigments to color the oxide film. According to the coloring mechanism and process, it can be divided into organic dye coloring, inorganic dye coloring, color paste printing color, over-color dyeing and achromatic dyeing. Wait. Electrolytic coloring is to perform AC electrolysis on anodized aluminum and its alloys in an aqueous solution containing metal salts, and deposit metals, metal oxides or metal compounds at the bottom of the porous layer of the oxide film. Shows a variety of colors. Electrolytic overall coloring means that aluminum and its alloys are colored at the same time as anodizing. It is characterized by one step of oxidation and coloring, and the colored film has good light resistance, heat resistance, corrosion resistance and wear resistance. Electrolytic overall coloring is further divided into natural hair color, electrolytic hair color and power hair color method, among which electrolytic hair color is dominant, followed by natural hair color, and power hair color is under development.

To create much more price for clients is our company philosophy; purchaser growing is our working chase for High Quality for China Aluminum Extrusion Profile for Building Aluminium Profile Hear Sink Industry, Hope we can make a more superb potential with you as a result of our attempts from the future.

High Quality for China Aluminum Extrusion, Aluminium Extrusion, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade items in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

-

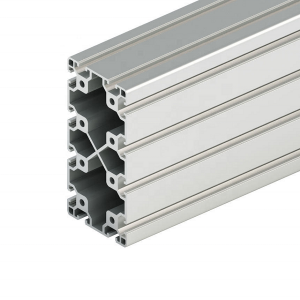

Wholesale China Wholesale 6061 7075 5052/5083/5...

-

OEM/ODM Supplier Hot Rolled Carbon Steel Coil a...

-

Leading Manufacturer for China Structural Steel...

-

ODM Supplier Mild Ms Carbon Steel 4mm 6mm 8mm 1...

-

Excellent quality Stainless Steel/Aluminum/Galv...

-

Wholesale China Wholesale 6061 7075 5052/5083/5...