Steel pipe is a hollow long strip of steel, which is widely used as a pipeline for transporting fluids, such as oil, natural gas, water, gas, steam, etc. In addition, it is lighter in weight when bending and torsional strength are the same, so it is also widely used Used in the manufacture of mechanical parts and engineering structures. It is also commonly used to produce various conventional weapons, barrels, shells, etc. Welded steel pipes, also known as welded pipes, belong to seamed steel pipes, which are steel pipes made of steel plates or strips after crimping and welding, generally with a length of 6 meters. The production process of welded steel pipe is simple, the production efficiency is high, there are many varieties and specifications, and the investment in equipment is small, but the general strength is lower than that of seamless steel pipe.

Welded steel pipe classification

Classified by production method

(1) According to the process – arc welded pipe, resistance welded pipe (high frequency, low frequency), gas welded pipe, furnace welded pipe

(2) According to the weld – straight seam welded pipe, spiral welded pipe

Classified by section shape

(1) Simple cross-section steel pipes—round steel pipes, square steel pipes, oval steel pipes, triangular steel pipes, hexagonal steel pipes, rhombus steel pipes, octagonal steel pipes, semicircular steel circles, others

(2) Complicated cross-section steel pipes – unequal hexagonal steel pipes, five-petal plum-shaped steel pipes, double-convex steel pipes, double-concave steel pipes, melon-shaped steel pipes, conical steel pipes, corrugated steel pipes, case steel pipes, etc.

According to the wall thickness, it can be divided into: thin-walled steel pipe and thick-walled steel pipe;

According to the shape of the end, it can be divided into: round welded pipe and special-shaped (square, flat, etc.) welded pipe;

Classification by purpose

General welded pipe, galvanized welded pipe, oxygen-blown welded pipe, wire casing, metric welded pipe, idler pipe, deep well pump pipe, automobile pipe, transformer pipe, electric welded thin-walled pipe, electric welded special-shaped pipe, scaffold pipe and spiral welded pipe.

The main purpose

It is widely used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction. It is one of the twenty key products developed by our country.

Used for liquid transportation: water supply and drainage. For gas transportation: gas, steam, liquefied petroleum gas.

For structural purposes: as piling pipes, as bridges; pipes for wharves, roads, building structures, etc.

Welded steel pipes are divided into galvanized and non-galvanized according to the surface treatment of the pipe. Welded steel pipes can be divided into two types when they leave the factory: one is threaded at the end of the pipe, and the other is not threaded at the end of the pipe. For welded steel pipes with threads at the pipe ends, the length of each pipe is 4-9m, and for welded steel pipes without threads, the length of each pipe is 4-12m.

Welded steel pipes are divided into thin-walled steel pipes, thickened steel pipes and ordinary steel pipes according to the thickness of the pipe wall. Ordinary steel pipes are the most used in process pipes, and their test pressure is 2.0MPa. The test pressure of the thickened steel pipe is 3.0MPa.

There are many connection methods for welded steel pipes, including threaded connection, flange connection and welding. The flange connection is divided into threaded flange connection and welding flange connection, and the welding method is divided into gas welding and arc welding.

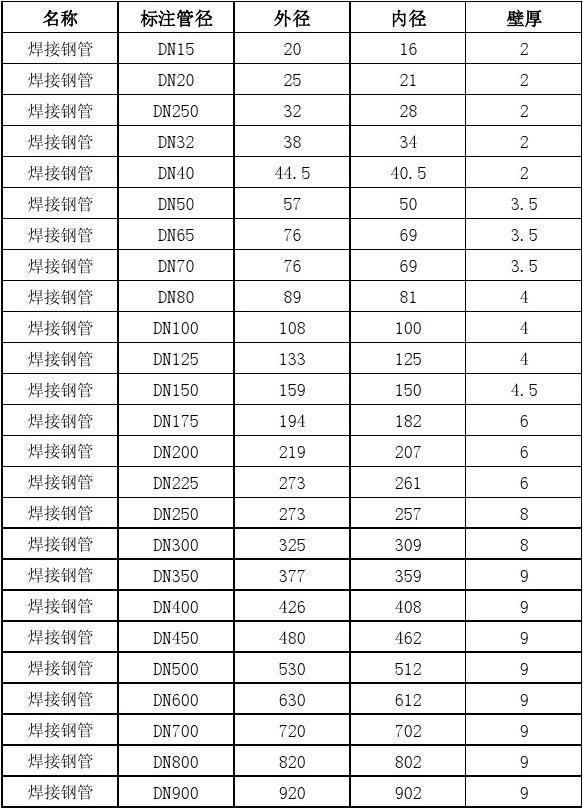

Commonly used welded steel pipe specification range: nominal diameter 6 ~ 150mm

Welded steel pipes can be roughly divided into three categories according to the forming process:

1. Electric resistance welded steel pipe

Electric resistance welded steel pipe, English name ERW (Electric resistance welded Pipe), weld type is straight seam. The resistance welding adopts the pressure welding method without filler metal. There is no filling of other components in the weld seam. The skin effect and proximity effect of high-frequency current make the edge of the plate instantly heated to the welding temperature, and the forging is formed by squeezing the extrusion roller. Tissue welds.

Resistance welded steel pipe can be divided into two categories: high frequency resistance welding HFW (High frequency welded pipe) and low frequency resistance welding LFW (Low frequency welding).

ERW steel pipes are mainly used to transport vapor and liquid objects such as oil and natural gas, and can meet various requirements of high and low pressure. Currently, they occupy a pivotal position in the field of transportation pipes in the world.

2. Spiral welded steel pipe

Spiral welded steel pipe, English name SSAW (Spiral submerged-arc welding pipe), weld type is spiral seam. The method of submerged arc welding is adopted, and the inner and outer double layers are welded. Submerged arc welding (including submerged arc surfacing and electroslag surfacing, etc.) is an important welding method, which has the advantages of stable welding quality, high welding productivity, no arc light and little smoke and dust.

The spiral welded pipe has a large diameter, which can reach more than 3000mm, and is more suitable for large-diameter pipeline transportation and building structures.

Three, straight seam welded steel pipe

Longitudinally Submerged Arc Welded Pipe, the English name is LSAW (Longitudinally Submerged Arc Welded Pipe), and the weld type is straight seam. The method of submerged arc welding is also used, and the inner and outer double layers are welded. The wall thickness of the straight seam steel pipe is relatively large, and its use is similar to that of the spiral welded steel pipe.

According to different forming processes, straight seam welded steel pipes can be divided into two categories: UOE (Uing and Oing forming pipe) and JCOE (J-ing, C-ing and O-ing pipe). UOE forming method (U forming, O forming, E diameter expansion), JCOE forming method (steel plate is pressed into J shape, then pressed into C shape and O shape in turn, and then expanded).

It should be noted that the submerged arc welding process (SAW) is a kind of electric fusion welding (EFW Electric Fusion Welded Pipe), which is to combine the metals by heating the metal between one or several consumable electrodes and the workpiece. One of the processes in which the arc fully melts the metal and the filler material without pressure, and the filler metal part comes from the electrodes.

Post time: Jan-06-2023