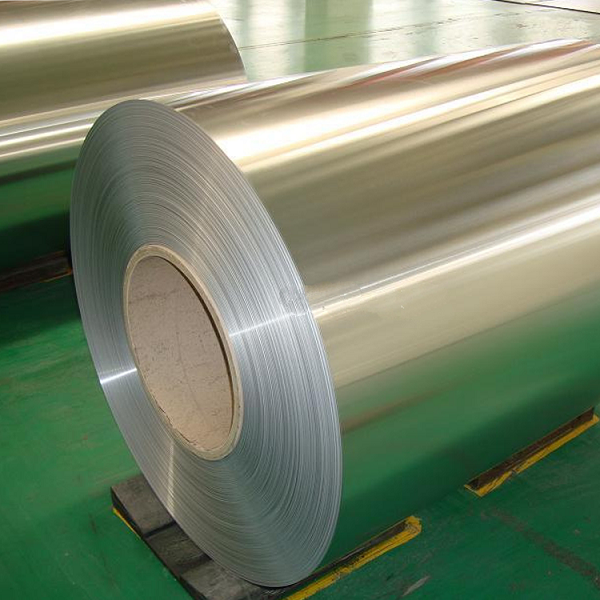

Professional Design Polished Aluminum Tubing - Thermal insulation aluminum coil – Rizhaoxin Detail:

Product Description

Thermal insulation aluminum coil has pure aluminum coil and alloy aluminum coil. Due to the characteristics that are very suitable for the harsh environment brought by construction and pipeline engineering, similar raw materials have been gradually eliminated. The main feature of thermal insulation aluminum coil is that it has strong survivability against corrosion and rust, so thermal insulation aluminum coil has developed rapidly in recent years.

1060 thermal insulation aluminum coil and 3003 thermal insulation aluminum coil are the most commonly used products in thermal insulation aluminum coil series, especially 1060 thermal insulation aluminum coil, which can account for as much as 70% in various thermal insulation industries, especially enough to see the thermal insulation aluminum coil in The whole industry and the insulation industry are widely used. 3003 thermal insulation aluminum coils are mainly used outdoors, and have high environmental requirements and high corrosion resistance requirements, such as coastal areas and long-term rainwater corrosion areas.

The use of thermal insulation aluminum coil. Insulation aluminum coil has a wide range of uses, especially for pipeline engineering, aluminum raw material is a very good choice. The anti-rust and anti-corrosion strength of the thermal insulation aluminum coil makes the aluminum coil have a very high life survivability, even in harsh environments. In contrast, iron raw materials do not have the ability to prevent rust, and can survive in a humid environment for about 3 years, while thermal insulation aluminum coils can last for decades.

Insulated aluminum coils are not only very successful in plumbing engineering. The application in daily life also has a very great ability. One of the large trucks and the outer surface of the oil tank is made of aluminum raw materials, and the thermal insulation aluminum coil is processed into an aluminum embossed plate, which has strong hardness and certain thermal insulation performance. The second common thermal insulation aluminum coil processed product license plate, the license plate is also processed from the thermal insulation aluminum coil, which has anti-rust and anti-corrosion ability and can resist the erosion of rainwater.

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for Professional Design Polished Aluminum Tubing - Thermal insulation aluminum coil – Rizhaoxin, The product will supply to all over the world, such as: Oman, Albania, Auckland, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

2022 High quality Aluminum Extrusion Profiles -...

-

Chinese Professional 5052 Aluminum Plate - 600...

-

High definition 6063 Aluminum Sheet - Stucco E...

-

PriceList for Painted Aluminum Coil - Thermal ...

-

2022 China New Design 1060 Aluminum Sheet - Th...

-

Super Purchasing for Aluminum Round Rod - Stuc...