4130 structural steel has high strength and toughness, high hardenability, and the critical hardenable diameter in oil is 15-70mm; the hot strength of steel is also good, with sufficient high temperature strength below 500 ℃, but at 550 ℃ Its strength decreases significantly; when the alloying elements are at the lower limit, the welding is quite good, but when the alloying element is close to the upper limit, the weldability is moderate, and it needs to be preheated to above 175 ℃ before welding; the machinability of the steel is good, and the plasticity is moderate during cold deformation; The range of 300 to 350°C has the first type of temper brittleness; there is a tendency to form white spots.

This kind of steel is usually used in a quenched and tempered state, and when the carbon content is the lower limit, it can also be used as a carburized steel that requires higher core strength. In the medium-sized machinery manufacturing industry, it is mainly used to manufacture quenched and tempered parts with large cross-sections that work under high stress conditions, such as shafts, spindles, and high-load steering wheels, bolts, stud bolts, gears, etc.; in the chemical industry It is used to manufacture welded parts, welded structures composed of plates and pipes, and high-pressure conduits whose temperature does not exceed 250°C in a medium containing nitrogen and hydrogen; in steam turbine and boiler manufacturing, it is used to manufacture fasteners that work below 450°C, Flanges and flange covers under high pressure below 500°C.

| Product Name | AISI 4130 Steel Round Bar |

| Standard | AISI 4130 |

| Material |

Q195、Q235、10#、20#、35#、45#、Q215、Q345、12Cr1Mov、15CrMo、304、316、321、20Cr、40Cr、20CrMo、35CrMo、42CrMo、40CrNiMo、GCr15、65Mn、50Mn、50Cr、3Cr2W8V、20CrMnTi、5CrMnMo, etc.

|

| Technology | Hot Rolled, Forged and Cold Drawn |

| Tolerance | Control with in the standard, OD:+/-1%, WT:+/-5% |

| Application | Small round bars of 5.5-25 mm are mostly supplied in bundles of straight strips, and are often used as steel bars, bolts and various mechanical parts; round bars larger than 25 mm are mainly used for the manufacture of mechanical parts, billets of seamless steel pipes, etc.

|

| Payment Terms | 1.FOB 30%T/T,70% Before shipment 2.CIF 30% Pre-payment , Balance must be paid before shipment 3.Irrevocable 100% L/C at sight |

| Third Party Inspection | SGS ,BV, MTC |

| Advantages | 1.Short delivery time

2.Quality assurance 3.Competitive price, 4.Free Sample |

| Delivery Time | Within 25 days after receipt of advance payment |

Round steel mainly includes round steel stainless steel and round steel carbon steel:

1. According to the process, round steel is divided into three types: hot rolling, forging and cold drawing. The specifications of hot-rolled round bars are 5.5-250 mm, of which, the small round bars of 5.5-25 mm are mostly supplied in bundles of straight strips, which are often used as steel bars, bolts and various mechanical parts; round bars larger than 25 mm are mainly For the manufacture of mechanical parts, tube blanks for seamless steel tubes, etc.

2. According to chemical composition, round steel carbon steel (that is, in terms of carbon content) can be divided into low carbon steel, medium carbon steel and high carbon steel.

3. According to the quality of steel, round steel can be divided into ordinary carbon steel and high-quality carbon steel.

4. According to the purpose, round steel can be divided into carbon structural steel and carbon tool steel.

The round steel is classified according to the production process: it is divided into three types: hot rolling, forging and cold drawing.

Hot rolled round steel is a pressure processing method in which the metal billet is passed through a pair of rotating rolls (various shapes), and the material section is reduced and the length is increased due to the compression forming and rolling of the rolls. This is the most commonly used production method for steel production. It is mainly used to produce profiles, plates and pipes.

Forged round steel: refers to round steel that can be shaped by forging. In general, the quality of the round steel produced by the free forging rolling method is better under the conditions of the same deformation ratio, because forging to achieve the same deformation amount of rolling requires repeated forging to elongate (forging is free deformation and rolling It is constrained deformation), so the same billet produces the same finished round steel forging is equivalent to an increase in the deformation ratio of rolling by more than 50%. In addition, in general, forging is the overall deformation of the steel from the surface to the interior and the rolling surface is deformed first, so The internal structure, segregation degree, metal flow line, etc. of the round bars produced by the two are completely different, and the quality of forged round bars is generally better than that of rolled round bars. Therefore, key components such as crane hook heads must be forged parts.

Cold-drawn round steel: also known as cold-drawn round steel, cold-drawn element steel, cold-drawn round steel, and smooth round steel, it is a kind of cold-drawn section steel. Whether it is cold-drawn round steel or round steel, its shape is round, but the surface of cold-drawn round steel is very smooth, its dimensional accuracy is high, and its mechanical properties are high. Because of its high dimensional accuracy, it can be used directly without processing.

Round steel has broad application prospects and is widely used in hardware, construction, automobiles, shipbuilding, petrochemicals, machinery, medicine, food, electricity, energy, aerospace, etc., building decoration. The most extensive processing of ordinary mechanical parts, general rod steel parts, CD rods, bolts, nuts.

|

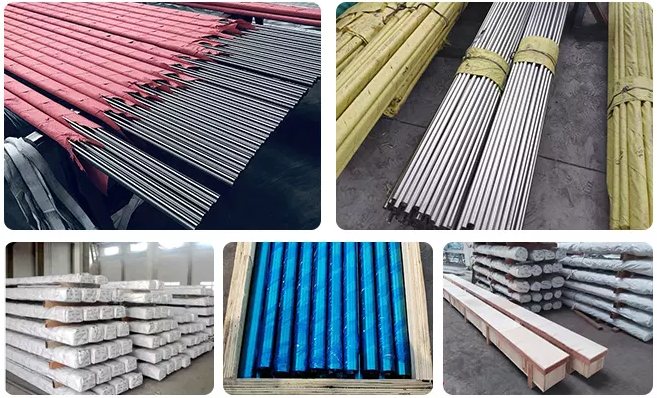

Packaging

|

Standard seaworthy export packing, other types of packing can be customized as every requirement.

|

|

Shipping packaging

|

Bundled with firm steel straps, easy for loading and unloading.

|

Q: Are you a manufacturer?

A: Yes , we are a Steel Round Bars manufacturer, We have own factory, which is located in Shandong,China. We have a leading power in producing and exporting various steel products. We promise that we are what you are looking for.

Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

Q: Do you have quality control?

A: Yes, we can accept BV, SGS third inspection .

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q:How can we get the offer?

A:Please offer the specification of the product,such as material,size,shape,etc.So we can give the best offer.

Q:Can we get the some samples?Any charges?

A:Yes,you can get available samples in our stock.Free for real samples,but customers need to pay the freight cost.

Q: How do you make our business long-term and good relationship ?

A: 1.We keep good quality and competitive price to ensure our customers’ benefit.

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.